Maintenance and Reliability Systems Assessment

Ready to take your asset reliability to the next level?

Figuring out where you stand – and identifying where you can improve – is the first step on any successful reliability journey moving your organization from a reactive situation to optimizing preventive maintenance, to condition-based/predictive maintenance, and finally to prescriptive maintenance. Once you know where you stand and where you want to go, then we can select the best condition monitoring technologies and platforms to ensure ROI and help you reach your goals.

Without this foundational review, digital investments could be wasted. Establishing and strengthening the basics is the first step to breaking out of a reactive maintenance approach and transforming into proactive work.

Allied’s Maintenance and Reliability Systems Assessment follows an effective, proven process that quickly identifies where your biggest gaps in reliability lie and where the greatest gains can be achieved. It is often stated that you must know where you are before you can get to where you are going. This holds true for organizations looking to develop an improvement initiative or bolster one already underway.

A Reliability Systems Assessment can help you:

- Gain an understanding of the maturity of your organization across all elements of reliability.

- Align the organization to a common reliability vision.

- Identify areas to optimize efficiency and effectiveness.

- Understand where to focus efforts and resources to realize the most value.

- Identify existing gaps and barriers to achieving the organization’s goals.

The Maintenance and Reliability Systems Assessment includes a period of data gathering and analysis, virtual and in-person interviews, self-assessments, and on-site follow-ups resulting in a business case for ROI and an actionable roadmap for a company to achieve its desired business goals.

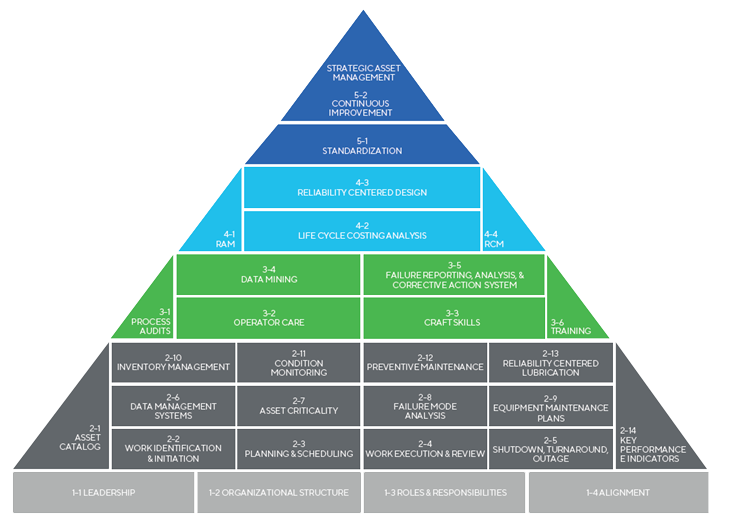

We base this analysis on our time-tested maintenance and reliability best practices methodology and associated Reliability Systems Model.

Typically, organizations only conduct internal benchmarking within their own industry vertical, but to truly achieve world-class operations, our Maintenance and Reliability Systems Assessment is based on reliability best practices compiled through our benchmarking efforts that cover over 3,500 plants across all industry verticals allowing you to adopt best practices from other industries as a competitive advantage.

Establishing a business case for change is necessary for your reliability review. Our method clearly maps out the financial impact of uncovering the hidden potential in your asset base to help you realize a higher return. Recognizing that business needs vary from organization to organization, Allied offers several alternatives for developing your business case and a complete analysis of the costs associated with conducting your improvement initiative.

Other Outputs from the assessment include:

- Site Close Out – close-out meeting at the end of the review period identifying high-level strengths and gaps with comparisons to best practices.

- Report – full report of the assessment findings, gaps, and recommendations.

- Reliability Roadmap – Your cross-functional team of champions and stakeholders work with Allied’s team to identify necessary reliability work streams and key roles on the team. The result is a detailed master plan that will close the gaps identified during the reliability system assessment, along with a communication plan for the governance structure and a list of performance metrics to measure success.

Get Started Today

Asset Reliability Capabilities: